Predictive Maintenance Records

All predictive maintenance must count on a record, not only a report’s record but also a record of the maintenance tasks that are performed on the assets. A good predictive maintenance management considers not only the documentation of the predictive inspection reports but also that of all the maintenance events of every asset.

Predictive maintenance events

The type of interventions that must be informed to the predictive maintenance analysts are:

-

Corrective

shafts alignments, seals replacement, balancing. -

Preventive or periodic

greasing, oil changes, cleaning. -

Proactive

bench reinforcement, automatic greasing system installation. -

Minor failure

when there has been no machine shutdown nor secondary damage. -

Major failure

when there has been machine shutdown or secondary damage. -

Other

The correct incorporation of the maintenance interventions or events allows the predictive maintenance analysts to be more assertive in their diagnosis. It is necessary to avoid understanding predictive maintenance as a guessing or speculative technology.

Many times, it happens that the maintenance department hides information from the predictive maintenance expert to contrast their diagnosis or to test the technological and diagnostic ability of the experts. Because of this reality, it is necessary to train all the personnel involved with the predictive technologies in order to know the scope and all the limitations of each technology and be able to understand the value of documenting the events on the assets.

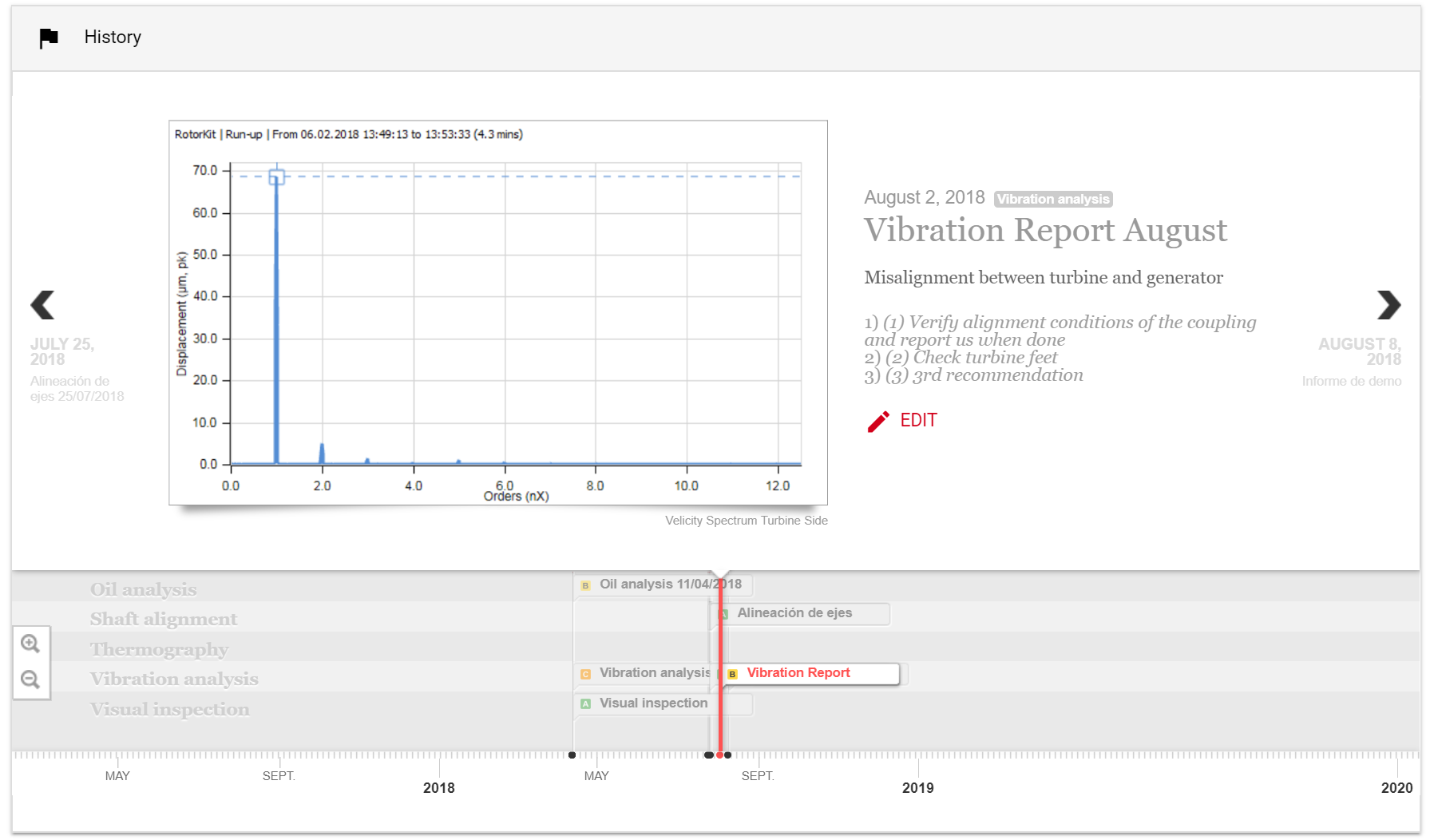

Predictive maintenance records visualization

Finally, it is important to correctly represent the record of the machine where the different predictive maintenance inspections as well as the maintenance events must be visualized using every available technology. Power-MI has an asset visualization function where a timeline of the record of the asset is shown. From there, you can access the corresponding report both in its short version and original version.

What is Power-MI?

Power-MI is a cloud based solution that allows you to design & manage your condition-based maintenance plan integrating all techniques into one platform. Easy reporting, automatic work orders and CMMS integration.

Read more