Vibrations Analysis Report: How to Request Machine Information

You have received the order to perform a vibrations analysis on a machine you have no record of. The first thing you must do is request the machine information from the maintenance department or the plant. Requesting machine information before performing a vibration analysis is crucial. Here we explain what you must do.

As we talked about in the post Information of the machines for vibration analysis it is essential to get the information on the machine before we even configure the vibration readings.

Advice:

Whenever possible, do not agree to go and analyze a machine without having all the information about it before. Part of the role of a good analyst is to collect the data of the machines.

Here you have the message I used to send my clients before configuring my vibration collection tasks and routines:

Dear <Name>:

Regarding the vibrations analysis that we will perform on <Name of the machine>, I ask that you please provide me with the following information before I configure the reading tasks:

-

Objective of the vibrations analysis.

-

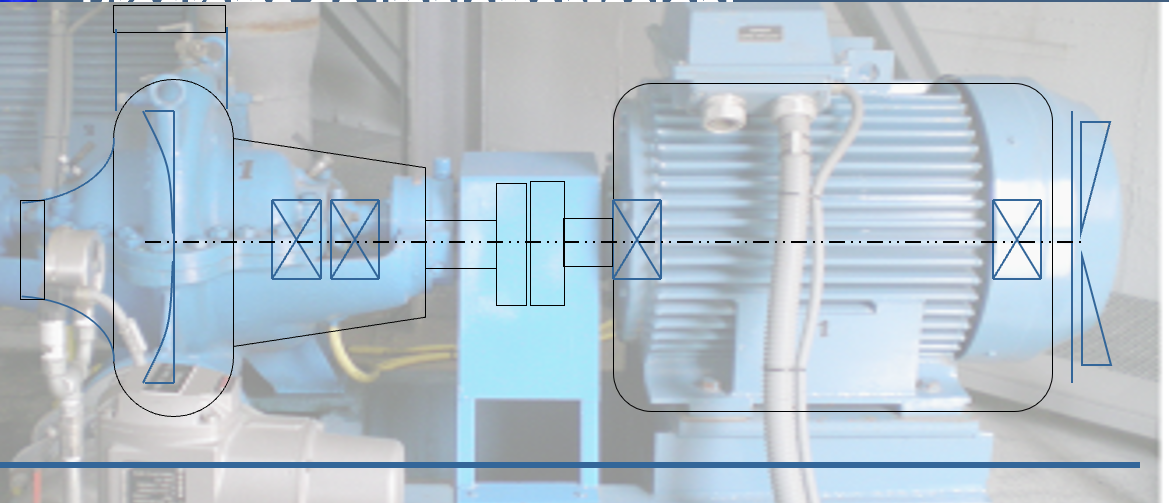

Scheme or blueprints of the machine: to identify the dynamic components and supports (bearings) of those components.

-

Rotating speed of the shafts (specify if it works at variable or fixed speed).

-

Motors: power (kW), number of poles and number of bars of the rotor.

-

Number and brand of the bearings.

-

Gearboxes: number of stages* and number of teeth of each wheel and sprocket.

-

Number of rolling elements (blades or vanes).

-

Coupling types.

-

Operational condition(s) (specify if there is more than one operational condition).

-

Application or process where the machine is involved.

-

Maintenance history.

-

Previous vibrations analyses.

-

Oil analysis, ultrasound, thermography, acoustic analysis or any other previous ones.

-

Other information available: installation report, operation hours, operation and maintenance manuals, operators’ oral testimony, process data, etc.

Remember that the reach of the diagnosis we make will depend on the information we have available on the machine.

Thank you for your cooperation in advance.

What is Power-MI?

Power-MI is a cloud based solution that allows you to design & manage your condition-based maintenance plan integrating all techniques into one platform. Easy reporting, automatic work orders and CMMS integration.

Read more