If You're Going to Align a Coupled Shaft Fan, Read This Before

Fans in the industry can be found in a wide variety of sizes and for different applications. In this article, I refer specifically to fans with direct coupling to the motor.

First of all, a little context. We all have an intuitive understanding of what a fan is for. The vast majority of industry fans use radial fans, which have a slightly different operating principle than axial fans, which we are probably familiar with from domestic applications. Thus, it is common to find radial fans in the industry for circulation or transport of air or gases, gases exhausting, or for cooling.

Misalignment in a fan occurs when the motor's axis of rotation is not collinear with the axis of rotation of the fan.

Misalignment in a fan occurs when the motor's axis of rotation is not collinear with the axis of rotation of the fan. Therefore, there will be dynamic efforts that cause mechanical damage to the coupling and bearings, as well as energy inefficiency in the transmission of mechanical power.

If your fan can operate regardless of electrical consumption, or the coupling or bearings operate within the lifespan specified by their manufacturers, it is best not to touch the machine unless there is an engineering study behind it to optimize its operation.

Now, if the fan has high vibration, breaks couplings during operation or its bearings do not last the expected life, it is very likely that you are facing a misalignment problem.

Diagnosing misalignment

Most companies I know often diagnose misalignment with vibration analysis. That's fine, as it can be done at any time during the fan operation. However, I always recommend, before proceeding to align a machine, to check the alignment condition before making any decision about it.

Don't wait for trouble to come to act

If your plant has a laser alignment system, always remember to measure the condition of the alignment periodically. Don't wait for trouble to come to act. You will most likely be surprised at how many machines are misaligned without being detected in vibrations.

Before aligning

Before aligning a fan, follow these tips that I give you. This can save you a lot of time, stress and misunderstandings.

-

Check the soft foot

Usually, machines are aligned without taking into account a possible soft foot. Before aligning anything, you should check for the possible existence of a soft foot condition. This factor is very important because it can make you waste a lot of time trying to align a machine, and the simple fact of tightening a screw in a soft foot with more or less torque will make the corrections not keep within the defined tolerances. Check all four motor feet, correct them if necessary, and proceed then to align.

-

Check the bench

Sometimes you will find that the benches are no longer as rigid or as leveled as they were at the installation. It is easy to find badly damaged benches due to the location of the machines, the local weather, leaks from the machine itself or from nearby machines ...

-

Turn the fan

You will be able to detect bent axis; There may be a bent shaft that is producing mechanical vibrations and has nothing to do with alignment.

-

Check the foundation of the machine

See if the ducts or supports anchored or welded to the machine could exert stresses on the axles.

Excellence is in the details

Aligning fans with laser equipment offers advantages not only of time and convenience, but we can achieve much greater precision than conventional methods.

When aligning fans

Keep in mind that the tolerance range will mainly depend on the manufacturer's specifications, the type of coupling, and the speed of the motor.

When moving the machine, make sure that the slit holes (rectangular holes, whose ends are rounded) will allow you to move the machine horizontally as much as you need. Likewise, keep the support surfaces of the motors clean so that the shims support it perfectly.

When tightening the bolts, keep in mind that you may be able to clamp the shim with the screw while tightening it. To avoid this common failure, place them leaving a small gap between the shim and the bolt so that tightening the clamping bolts does not cause such a failure.

If you want to save time, use a suitcase with calibrated shims. The time saved is enormous.

As much as possible, do not put more than 4 shims for leveling. You will avoid the accordion effect.

To correct misalignment, move only the motor if possible

In more than 95% of machines, the motor is usually the one that is primed for corrections and usually the easiest to move. In the case of fans, moving the fan could create stresses in the ducts.

Make vertical corrections first, then horizontal corrections. Otherwise, the time spent correcting the horizontal misalignment would be lost, as lifting the motor to add or remove gauges to correct the vertical misalignment would cause horizontal movement that would affect our horizontal alignment work.

Always after correcting and tightening the motor holding bolts, take one last measurement to make sure the alignment is within the tolerance ranges.

It is a good practice, because sometimes when moving the machine and retightening the screws, it will not always be exactly where we intended. We must obtain the final values of alignment once all the screws are tightened.

After aligning

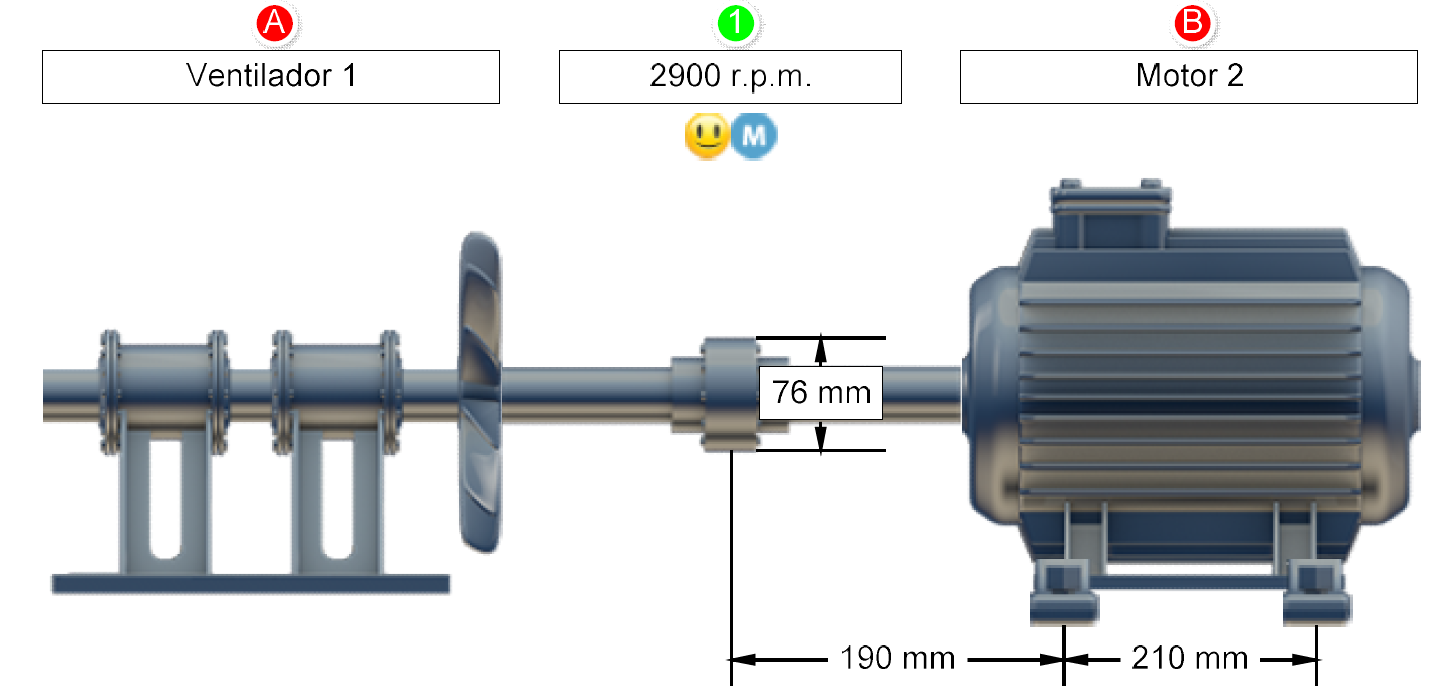

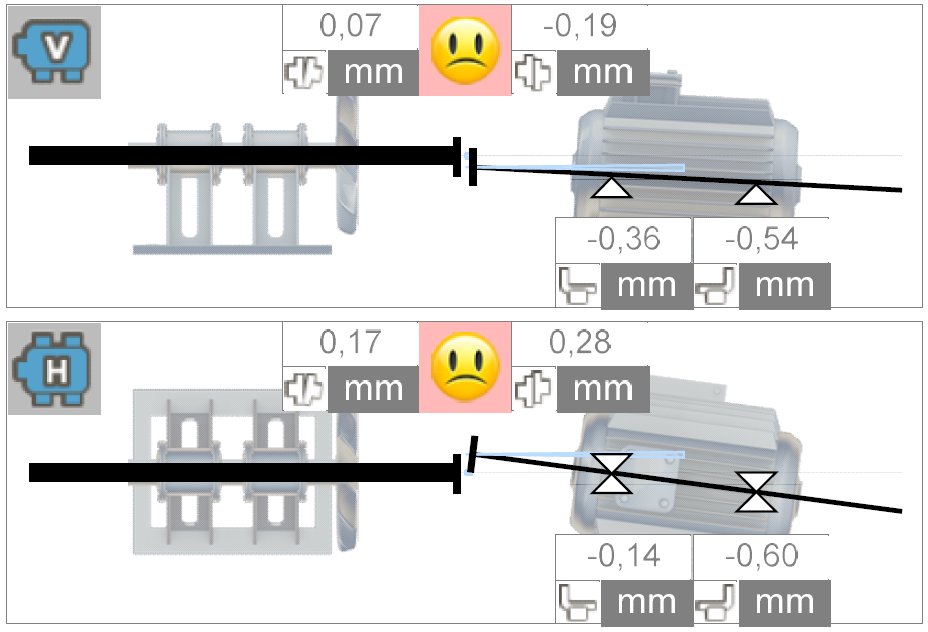

It is necessary to record the work done. In the images below you can see graphs of the reports that I use with the ARC 4.0 software from Pruftechnik. The equipment I usually use for alignments is a Rotalign TOUCH from Pruftechnik.

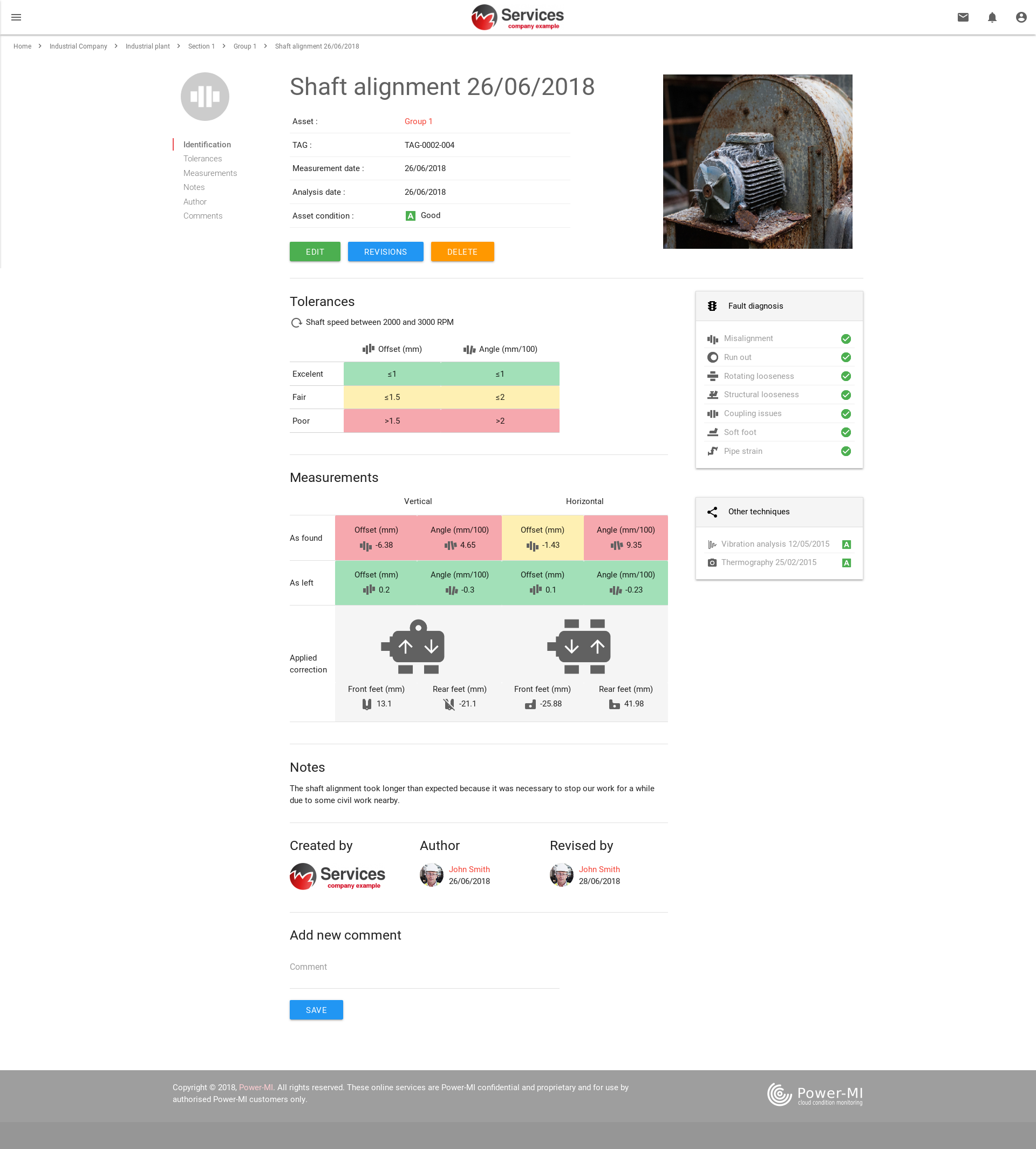

You can also make your reports with a Word template that takes a long time or with the Power-MI software (www.power-mi.com) which already has templates to fastly write your report and manage the results. The important thing is to document the work done. Similarly, I recommend saving a report of the starting and ending states of the alignment.

When the machine is put into operation, it is necessary to measure its vibrations in its temperature and operating conditions to verify its good condition.

Sometimes things get complicated

Sometimes thermal expansions are not taken into account if the fan operates at high temperatures, such as furnace draft fans. If that's the case, you need to check with the manufacturer for alignment targets, calculate these thermal expansions, or measure them.

How to measure thermal expansions? That is the subject of another article, but for now, I can tell you that you can measure them with the PERMALIGN equipment from Pruftechnik. I must tell you that, being in the field and without the PERMALIGN at hand, I have measured thermal expansion in a slightly more daring way: I start the machine, wait for it to reach its operating temperature, and measure under hot conditions.

It may be the case that if the fan bearings have a lot of clearances, the fan will have a slight displacement when it starts operating. That has not happened to me, but I do know of colleagues who have had this problem.

What is Power-MI?

Power-MI is a cloud based solution that allows you to design & manage your condition-based maintenance plan integrating all techniques into one platform. Easy reporting, automatic work orders and CMMS integration.

Read more