Types of Predictive Reports

As a vibrations analyst, I made the mistake of sending the same type of report to all my clients irrespective of the context in which I was performing the analysis. If I had known what I’m about to tell you, I would have saved a lot of time.

There are two types of predictive maintenance reports:

-

Deep analysis report

-

Periodic inspections report

In the deep analysis reports, an assessment is performed to detect the origin of a failure causing a problem on an asset. Generally, the predictive maintenance expert is called to carry out an examination of a machine. The development of the report requires documenting the inspection performed and evidence of the detection of the cause. Generally, these reports are later used for warranty claims, insurance or as a support for the manufacturer of the asset.

The periodic inspections reports are simpler. They are developed after a routine inspection of several assets as part of the predictive maintenance plan. The objective is to determine the operating condition of the assets and their evolution over time to identify any anomalies and later recommend corrective measures.

I’m going to tell you about my mistake: when I was hired to perform periodic inspections of machines, I would deliver deep analysis reports to my clients. This means that I was wasting time documenting each analysis when my clients simply wanted to know about the condition of their machines and what they should do to improve their reliability.

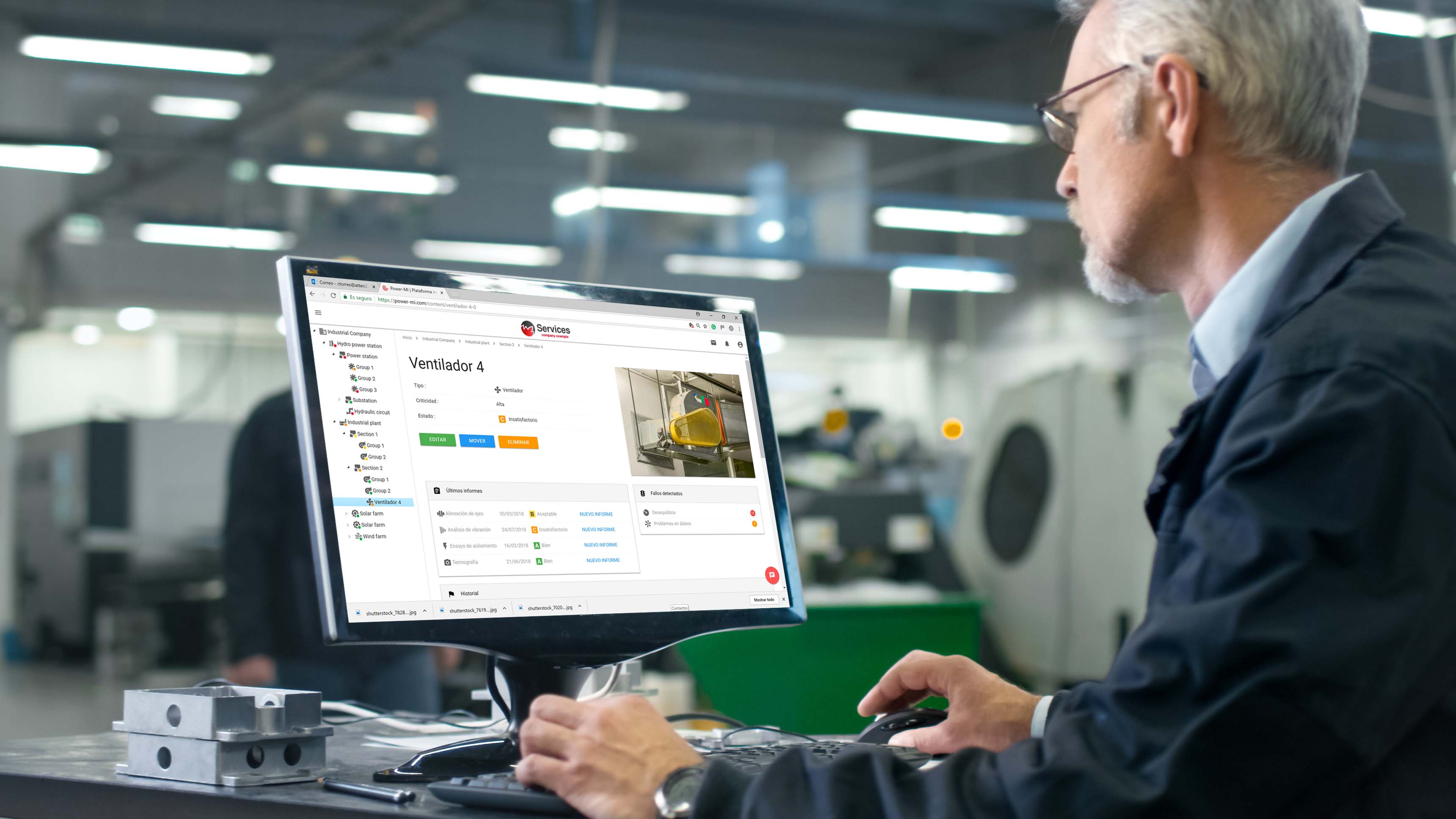

I recommend you start doing your predictive maintenance reports quickly and simply. To do so, we have developed Power-MI, where you can create deep analysis reports as well as periodic inspections reports.

What is Power-MI?

Power-MI is a cloud based solution that allows you to design & manage your condition-based maintenance plan integrating all techniques into one platform. Easy reporting, automatic work orders and CMMS integration.

Read more