Diagnosis Predictiva Brings Its Services to Industry 4.0 With Power-MI

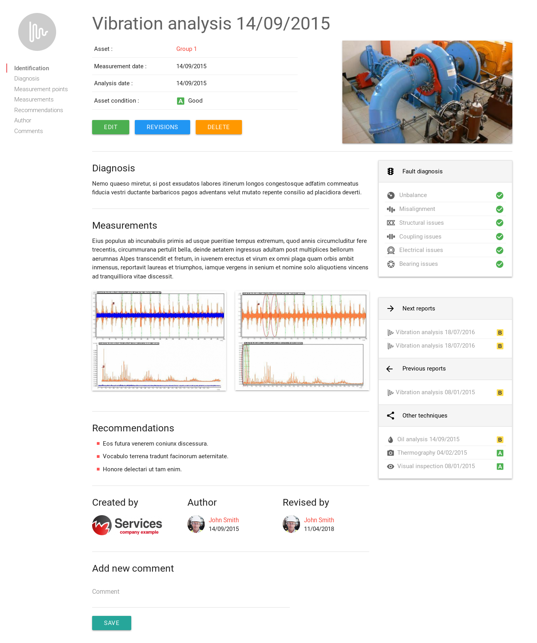

In order to improve the tracking and format of their predictive maintenance reports and provide a more personalized service to their customers, Diagnosis Predictiva, a predictive maintenance company, integrated into their workflow the Power-MI platform.

In the search to improve its services of vibrations analysis, ultrasound and laser alignment for its clients, Diagnosis Predictiva decided to use Power-MI to reduce the time of edition of predictive maintenance reports and standardize the format of all the reports. Thus, customers obtain consolidated information on the status of their assets through dashboards.

According to Oscar Domínguez, technical director of Diagnosis Predictiva, the predictive maintenance management platform changed its operation, saving time, avoiding errors, and allowing a more professional presentation of its reports. "You have a better visualization of the results and save time when I make the reports, and I have access to all the information at any time from any device with access to the application."

By having the information at hand, the optimization of time has allowed him to observe the usual assumptions in the creation of reports: "although it seems that it is enough to base a previous report, even from the same machine, it always takes time to modify it and adapt it for the new content."

Their experience, in addition to the increase in productivity, is also reflected in the standardization of the reports and their review, since the report no longer depends on the person who makes it or the brand of the equipment used.

The recommendation given by Óscar Domínguez to predictive maintenance analysts is simple: "to measure the time it takes to make a report and compare it."

One of the biggest challenges of the industrial sectors during this new technological stage is in the management of the predictive maintenance of industrial assets, the documentary unification in maintenance reports and their subsequent use in open IT environments.

To resolve these issues, provide follow-up and provide predictive maintenance structured data, Power-MI offers a platform in the cloud, updated in real time that facilitates the work of both clients and analysts in the field. Take the decisive step to the new stage of the industry and start your free trial for 30 days here.

Power-MI is a cloud-based Industry 4.0 workplace that allows managing predictive maintenance professionally, and it is extremely easy to use. The development of all software functionalities is based on user feedback. This enables us to continuously improve our solution while keeping it intuitive and straightforward for optimal user experience.

What is Power-MI?

Power-MI is a cloud based solution that allows you to design & manage your condition-based maintenance plan integrating all techniques into one platform. Easy reporting, automatic work orders and CMMS integration.

Read more